Hydraulic fracture dynamics

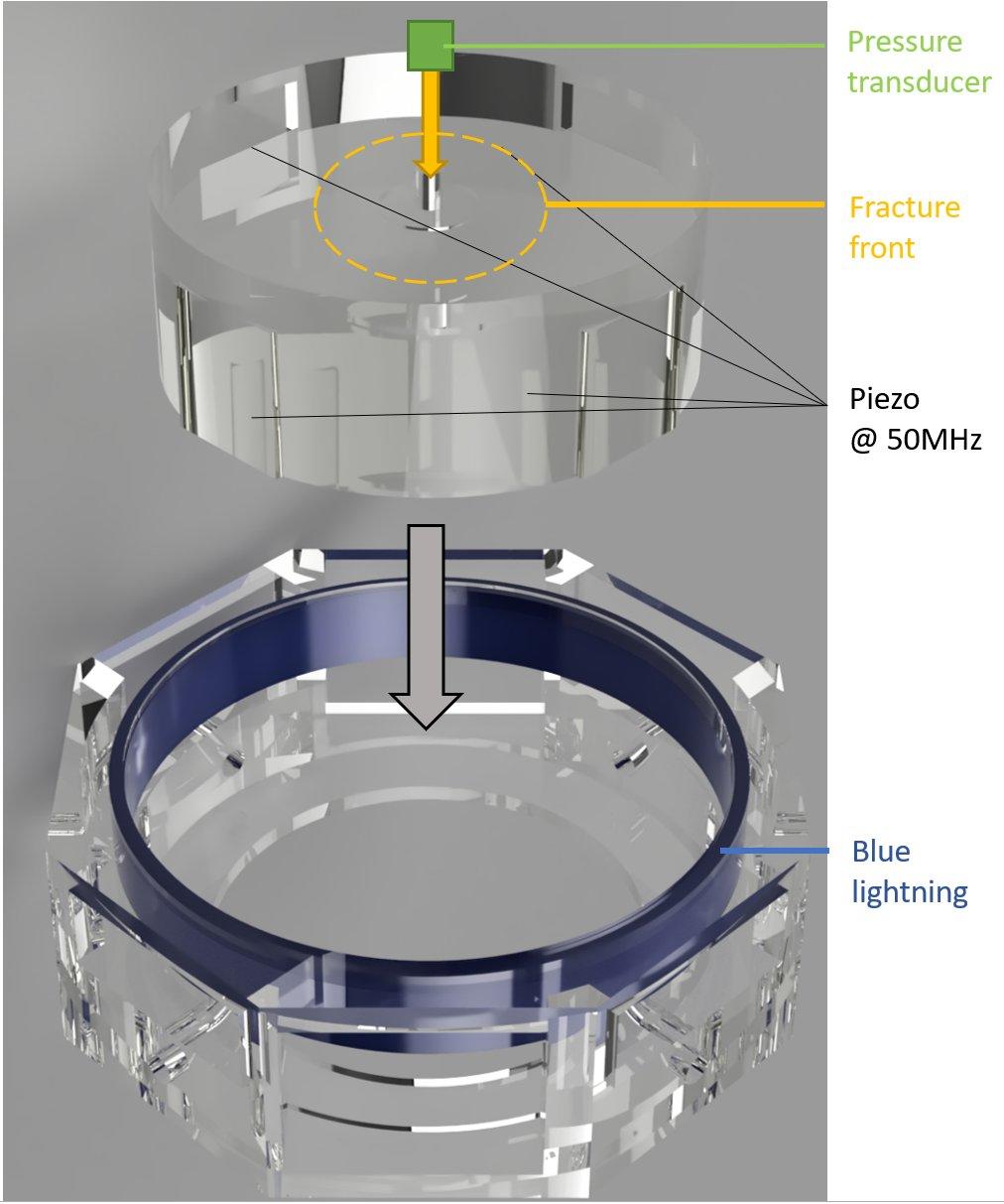

Hydraulic fracking of shale reservoirs is a process in which a highly pressurized fluid is injected into a rock formation, inducing fractures that create a connected path between the pores filled with hydrocarbons. Understanding the dynamics of those fractures is challenging as they grow quickly in opaque high strength materials and because they are difficult to predict. In the lab, the high strength material is thus made transparent by using stereolithography 3D printing (3GPa). The high-speed visualization is made possible by combining high speed imaging (75kHz) and piezoelectric transducers (>50 MHz). As a result, we made the first experimental observation of multiple dynamics during the fracture propagation due to different levels of energy dissipation.

|

|

Left - Experimental setup. The 3D printed block is inserted in a safety box containing the lightning.

The high-speed camera (under the experimental setup) allows to visualize the fracture propagation

Right - Result of the hydraulic fracture experiment. In red: Tracking of the fracture front

Experimental Investigations of Oil Transport in Porous Media

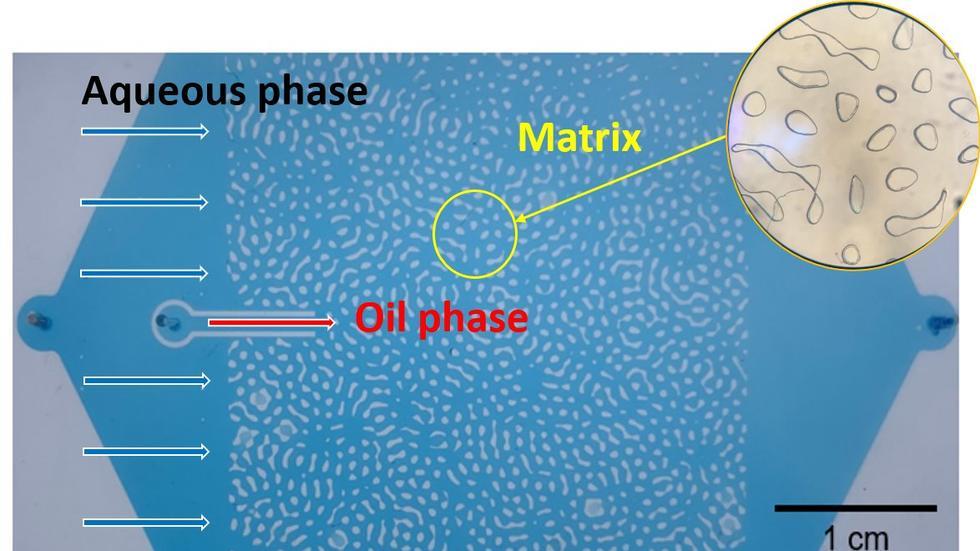

The understanding of immiscible flow in porous media is a major interest for oil and gas recovery in conventional reservoir. After the secondary oil recovery (water flood), the oil network becomes disconnected in the porous structure into ganglia. To understand how a single oil ganglion is being transported in such condition, we design an artificial porous media where we can tune the main parameters such as pore size, porosity, and connectivity, that we transfer into a microfluidic chip. Thanks to our design, we can push with surfactant or polymer-based solutions this oil ganglion and track it using high speed imaging technologies. We observed that the oil transport is achieved through several mechanisms: continuous transport, break up into droplets but also, under certain condition, coalescence of oil droplets. These dynamics leads to new understanding and perspectives for modelling the oil transport in porous medium.

|

|

Left - Microfluidic chip with a microscopic view of the pore structure. The aqueous phase (Water, polymer or surfactant-based solution) is injected from the left to the right The oil ganglia is generated thanks to the central channel.

Right - Surfactant-based solution pushing an oil ganglia. White: Oil. Blue: Porous media matrix. Black: Surfactant solution

Experiment, Simulation and Machine Learning Approach of Steady Fluid Flow in Porous Media

Fluid flow in porous media has a wide range of applications from geophysics to bio engineering. Each porous media has its own singularity defined by its porous geometry; thus, it is responsible for the flow dynamics within. The porous media’s geometry plays a complex role in the fluid dynamics. To better understand how the porous media structure, change the flows, we randomly generate 2D porous medium. From that we can study some geometrical components such as: pore length, tortuosity, porosity, etc. and using machine learning, compare how those parameters play a role in the fluid dynamics experimentally and numerically characterized. This study, based on 2D porous media, is then used to extend the machine learning to understand flows in 3D models and more complex system by introducing particle flows and different porous media surface properties.

Example of 100 generated random porous media (black: Matrix. White: Pores)

Contact: Thomas Cochard cochard@seas.harvard.edu